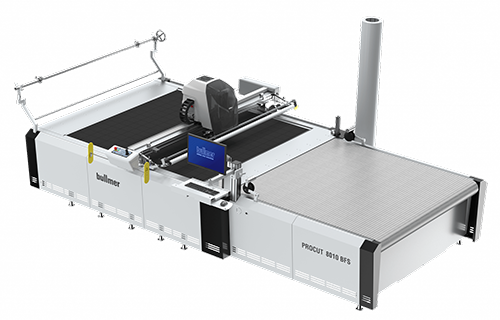

The new PROCUT GENESIS 8010 BFS is the support for professional cutting and offers all the features you expect from a bullmer machine.The low consumption as well as low power consumption ensure comprehensive resource conservation. Jointly adjacent cutting lines make even more efficient use of material and reduce waste. Simple cut parts can be programmed in just a few steps directly on the machine. In addition to pure cutting, drilling of holes is also possible.

- Bitefeed cutting

- Touchscreen

- Automatic knife drive oiling system

- Operator guidance with plausibility check and error massages

- Grinding unit wit self adjusting grinding wheels

- Brushless permament magnet drive for all axes

- Integrated high-performance vacuum turbine 13.5-17.5 kW

- Drill function

The new PROCUT GENESIS 8010 BFS is characteristed by high performance and economy in its class and that’s a reason why this cutter is ideal for the automotive industry or furniture upholstery.

Our Procut is equipped with a vacuum pump, which provides a strong and stable hold on the material during cutting and is therefore ideal for the clothing industry.

Mainly permeable materials, for others, we suggest to confirm cutting.

The PROCUT GENESIS 8010 BFS offers a high degree of machining flexibility in its class and is economical, even at low capacity utilization. The operating logic and menu navigation are geared to the needs of the operator. It offers an easy entry into professional cutting with an excellent price/performance ratio. Increase your productivity through cost-effective complete processing with low space requirements. Thanks to the jointly adjacent cutting lines, material is used even more efficiently and waste is reduced.

Conntection parameters

Total maximum Energy demand 23.5 kW

Protection 3x 63A

Cross section of electric cable 5x16mm

Compressed air 200l/m, with drill option